Company Profile

Development History

Corporate Culture

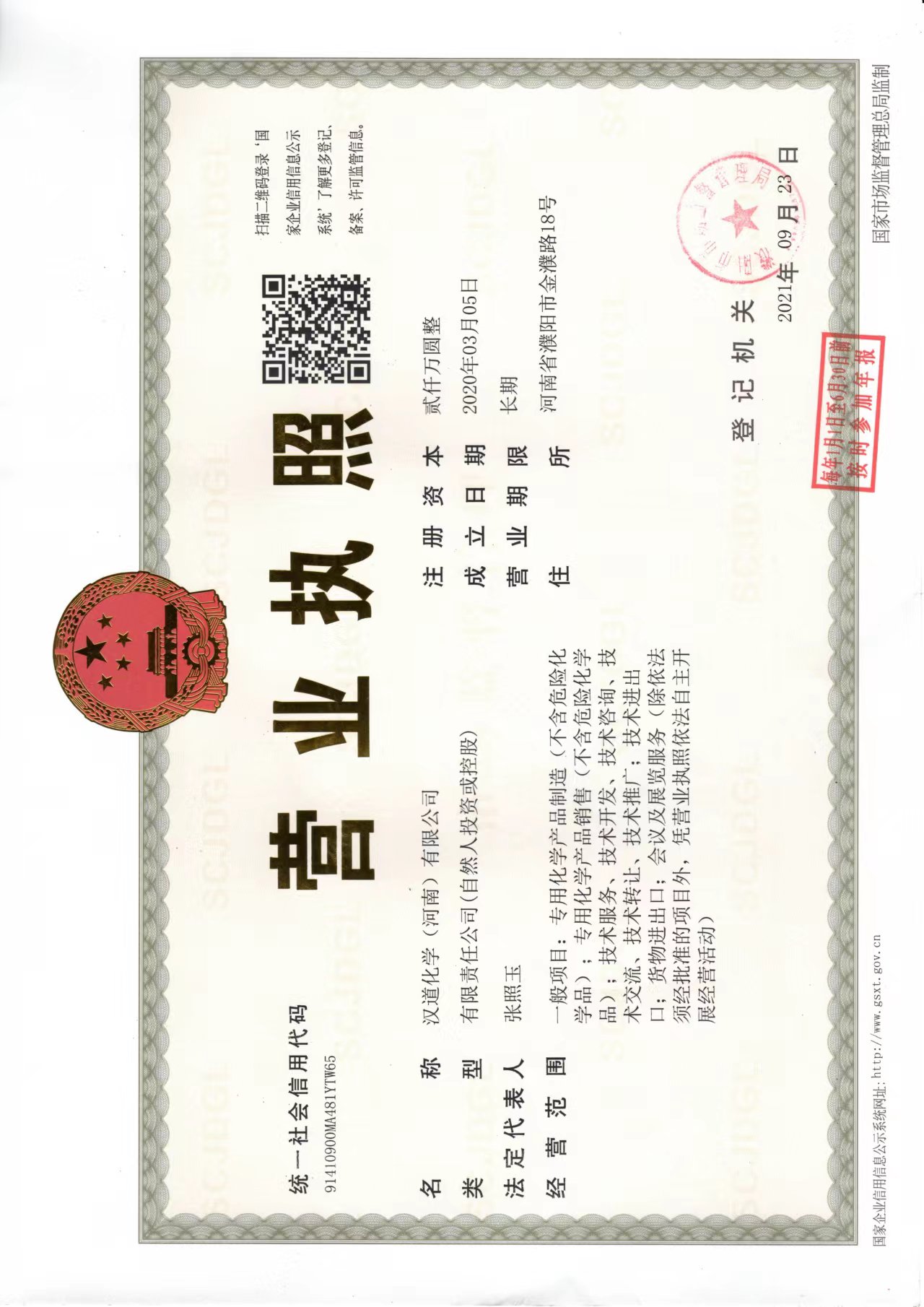

Qualifications and Honors

Technology Center

Video Showcase

Handow Family Members

Redispersible Polymer Powder (RDP) and Polymer Emulsion: Professional Support for R&D and Testing

In the field of construction chemistry and high-performance materials, redispersible polymer powder (RDP) and polymer emulsion have become crucial materials for product upgrading. Our professional R&D and application testing laboratory provides you with specialized services for technical support and performance optimization.

I. Core Capabilities of the Technology R&D Center: From Molecular Design to End-Use Application

- Handow Chemical Technology Research Center

- Handow Chemical Technology Research Center

- Handow Chemical Technology Research Center

1. Formula R&D Polymer Structure Optimization: Adjust the molecular weight, glass transition temperature (Tg), and functional groups of polymers to improve the flexibility, bonding strength, and weather resistance of products. Encapsulation Technology Research: Enhance the redispersion stability of redispersible polymer powder to ensure effective redissolution in dry-mix mortar. Functional Improvement: Develop special emulsions (low-volatility, alkali-resistant types) to enhance the water resistance, environmental friendliness, and durability of building materials.

2. Performance Testing Basic Physicochemical Index Testing: Solid content, viscosity, pH value, particle size distribution, minimum film-forming temperature (MFFT). Core Performance Verification: Bonding strength (cement-based / non-cement-based substrates), flexibility / flexural and compressive strength, water resistance / alkali resistance, open time / slip resistance, temperature cycle stability (environmental simulation from -30℃ to 70℃). Construction Simulation Testing: Simulate actual construction conditions in a laboratory environment (temperature and humidity changes, substrate water absorption rate).

3. Application Solutions Dry-Mix Mortar System Optimization: Formula development for tile adhesive, putty, self-leveling mortar, thermal insulation mortar, waterproof mortar, etc. Performance Improvement of Coatings and Sealants: Enhance film adhesion, scrub resistance, crack resistance, and elasticity of coatings. Customized Services: Provide personalized product solutions for specific substrates, climate conditions, or construction processes.

II. Our Technology R&D and Application Center Can Provide You with Professional Support

- Handow Chemical Technology Research Center

- Handow Chemical Technology Research Center

- Handow Chemical Technology Research Center

Professional Team: Composed of professionals in polymer chemistry and building materials science with rich industry experience.

Advanced Equipment: Equipped with professional instruments such as rheometers, electronic universal testing machines, laser particle size analyzers, and artificial climate aging chambers.

Standard Certification: Tests comply with domestic and international standards such as GB, JC, ISO, and EN to ensure data accuracy.

Efficient Services: Provide an efficient transformation path from formula prototype to application feedback.

Whether you are committed to developing environmentally friendly building materials with better performance or seeking improvement and upgrading of existing products, our laboratory will provide you with support from basic research to industrialization implementation with professional technical capabilities.